Installation

Engineered Wide Plank Flooring Installation Guide

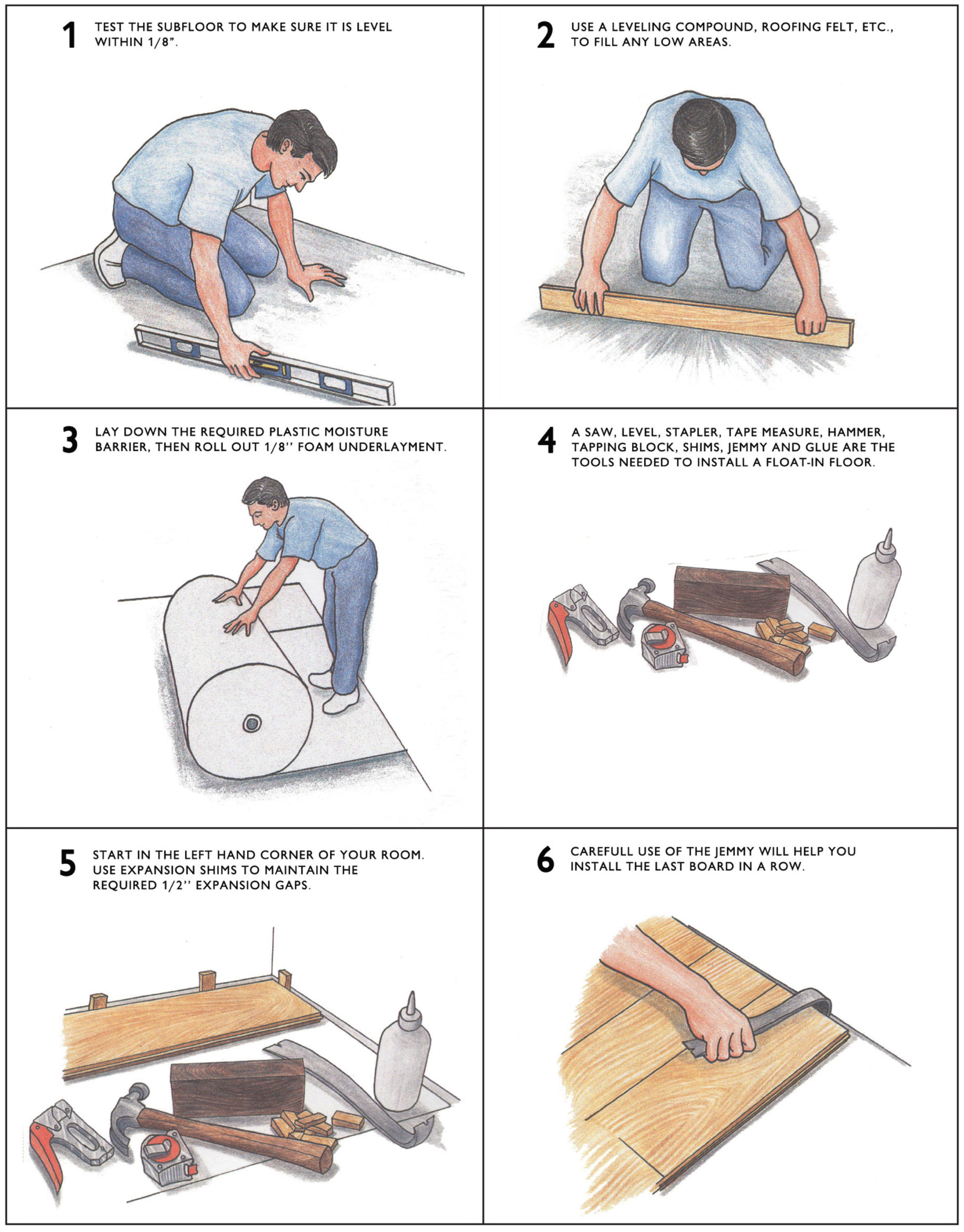

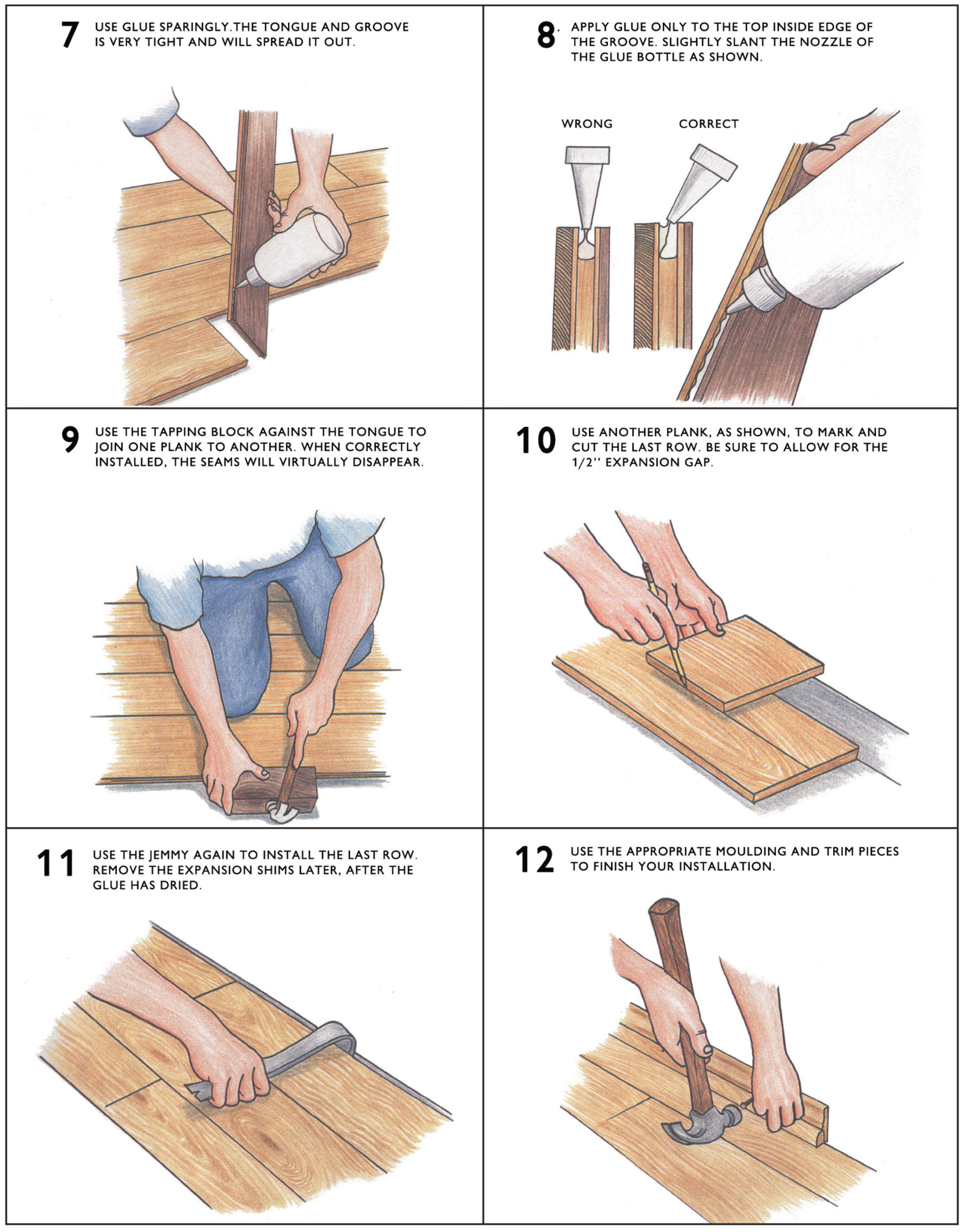

Recommended Installation Methods

Our engineered wide plank floors can be installed using three standard methods: nail down, glue down, or floating. Based on width and application, we recommend the following:

• 6″–10″ wide planks: Floating installation is preferred

• Traditional installations: Nail down is the standard recommendation

Why Choose Floating Installation for 6"–10" Wide Planks

Floating installations offer key advantages for wider engineered planks:

• Faster and easier to install with minimal tools

• Ideal for use over radiant heat systems

• Takes full advantage of our flooring’s exceptional dimensional stability

• Eliminates the cost and complexity of adhesives or nails

Pre-Installation Planning Tips

To ensure a visually stunning finished floor, we suggest the following steps before installation begins:

• Dry lay the boards: Arrange planks on the floor before fastening to preview layout

• Blend grain and color patterns: Work with your installer to balance:

– Grain movement and orientation

– Color variation between boards

– Natural character features (knots, streaks, mineral lines)

• Use shorter boards creatively: Install shorter lengths at row beginnings or ends to achieve a natural “Classic Random Length Pattern” and reduce visible repetition

How to Calculate Materials

When placing your order:

• Add 15% extra to your total square footage

– This covers trimming waste during fitting

– It also ensures you have matching material for any future repairs or board replacements

For complete details, including subfloor requirements, acclimation guidelines, and finishing tips, please refer to our full installation guide.